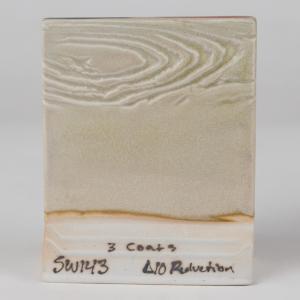

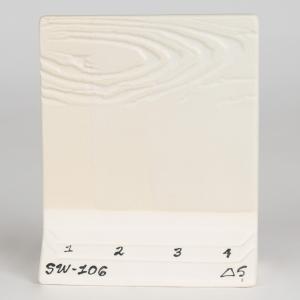

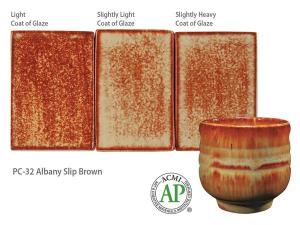

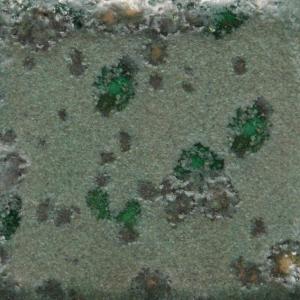

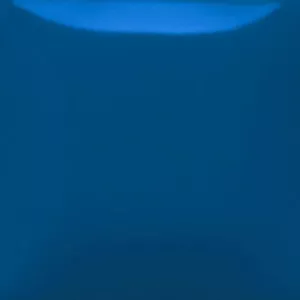

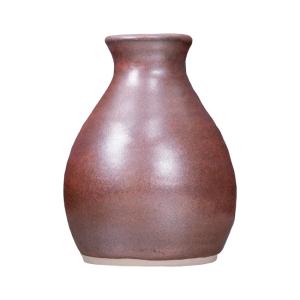

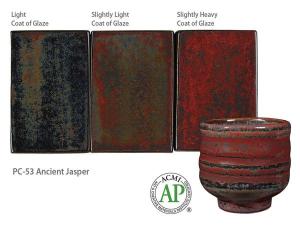

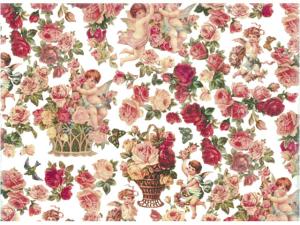

Glazes can be glossy, matte or with effects, depending on the glaze you choose. The glazes are available ready-mixed as a brushing glaze and some are available in powder form (dry) as a dipping glaze. All our glazes melt at 1000°C (earthenware glazes) or 1210-1230°C (stoneware glazes). When fired at higher temperatures, some glazes may change colour. Colour and effects vary depending on the thickness applied, firing temperature, firing schedule and clay. The colour samples shown on the website are fired horizontally at 1000°C (earthenware) 1210°C (stoneware) on white clay with a curve of about 7-8 hours without holding. Decorations with decals and liquid gold are applied to glazed ceramics to be fired at 800°C.

Which glaze should you choose?

Ceramic glazes come in many varieties – from transparent glazes to reactive effect glazes. The choice depends on the type of clay you are using, the firing temperature, and the result you want to achieve. Some glazes create clean, solid-colored surfaces, while others produce depth, patterns, or crystal effects.

At Art4Fun, you’ll find glazes for both earthenware (1000 °C) and stoneware (1210–1240 °C), available as brush-on glazes or dipping glazes. We also offer underglazes and slips, which are applied before glazing to create decorative details. If you’re looking for something more experimental, we also carry glazes for raku firing.

Feel free to explore our different glaze types:

Stoneware glazes 1200 °C – for high firing with durable and expressive surfaces

Earthenware glazes 1000 °C – suitable for hobby ceramics and school use

Brush-on glazes – applied with a brush, offering control and detail

Dipping glazes – applied by dipping into a glaze bath

Underglazes and slips – used before glazing

Raku – special glazes for low-temperature, smoky firing

Need help choosing the right glaze for your project? Contact us and we’ll be happy to guide you.

It is important to always test an unfamiliar glaze before applying it to production work, as not only the clay can affect the final result, but also the thickness of the glaze application, the firing schedule, how fully loaded the kiln is, and the age of the kiln. The clays we sell generally work well with our glazes.

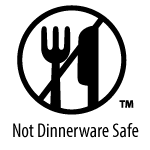

Most of our glazes are food safe. Those that are not are clearly marked with a warning symbol on the container and in the product description on our website. Food safe means that the glaze withstands acidic foods and contact with cutlery without the glaze surface being affected. When working with glazes, eating, drinking, or smoking should be avoided, and dust formation should be minimized.

Our glazes work well on clays from Georg & Schneider and Laguna. If other clays are used, please test first.